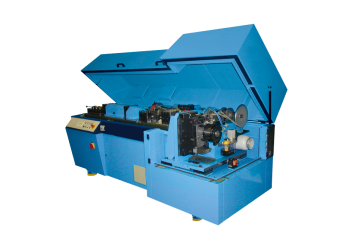

PrecisionShape EB9

The PrecisionShape EB9 is designed for finishing straightened and cut blanks measuring 4-10 mm in diameter and 50-150 mm in length.

The blanks are filled in a hopper and positioned in line by means of a step feeder. A notched wheel then separates the blanks and places them in the processing position. Machining units on each side chamfer the sides of the clamped blanks simultaneously in a dry machining process according to the tool geometry. Chips are separated by means of two chip bells. After machining, the notched wheel ejects the parts once they are released from the clamping station. The system has replaceable processing heads using standard cutting inserts.

Technical features

1. Perfect for post-processing

Mechanical finishing system. End machining on both sides for axles and shafts. Separation via notched wheel (parallel axis). Clamping station for clamping and positioning during processing.

2. Can be used flexibly

Two replaceable processing heads. Chamfering geometry depending on tool geometry.

More machines for end machining from our portfolio

PrecisionShape MJE

The PrecisionShape MJE from Jouhsen Bundgens processes wire ends faster than any conventional machine and with high precision.

PrecisionShape MJE2

From ring to finished part in a single work step – flexible end machining at high speed with the PrecisionShape MJE2 from Jouhsen Bundgens.

PrecisionShape UER

The PrecisionShape UER is the machine series for the production of pins with rolled ends.

Do you want more information about the PrecisionShape EB9?

Get in touch, we will be happy to help you.