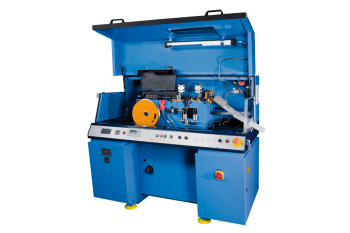

PrecisionCut MJC

PrecisionCut MJC is the series that offers a high output for short cut-offs. Wire is fed into the machine with great precision at a very high speed via a lever with infeed jaws. During the cutting process, the wire is held firmly by a fixed clamping unit with clamping jaws. Parts are cut by a bushing-on-bushing cutting system, providing a burr-free and straight cut.

The machines of this series are optimized for short lengths and a high output of up to 800 units per minute. The tried and tested machine elements such as high-precision guides and the drive shaft are easily accessible and mounted on a cast-steel plate. This makes adjustment and maintenance easy.

Technical features

1. Zero-vibration design

Vibration-free design with precision-ground, exchangeable linear guides for tool fitting. Infeed and cutting systems are cam driven using a split cam design.

2. Simple tool changes

Tools can be exchanged quickly and conveniently for changing wire diameters. Part lengths can also be easily adjusted.

3. Flexible during straightening

Straightening is done either by a rotating straightener or roller straightener.

4. Enclosed housing

The closed machine housing keeps noise levels low and is easily accessible on all sides. Drive, electronics and central lubrication are integrated in the machine housing.

5. Special-purpose versions

Special-purpose versions on demand.

More machines for straightening and cutting

PrecisionCut MJCE

The PrecisionCut MJCE is a straightening and cutting machine powered by linear motors. It can process thin wires without contact with oil.

PrecisionCut UD

PrecisionCut UD is the comprehensive engineering series with a trusted and robust machine design. It provides good straightening results even for longer cut-offs.

Do you want more information about the PrecisionCut MJC?

Get in touch, we will be happy to help you.